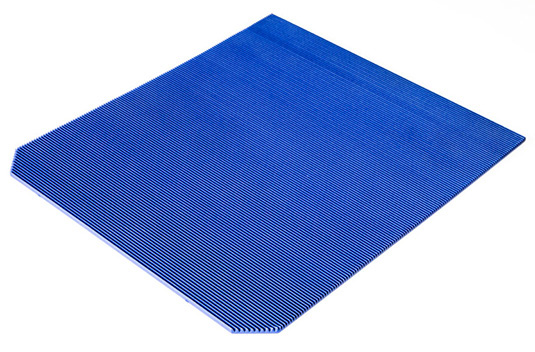

PTFE-BESCHICHTUNGEN, ANTIHAFTBESCHICHTUNG, KORROSIONSSCHUTZ

Mit gebündelter Kompetenz und Erfahrung in der Antihaftbeschichtung voraus

Eine PTFE-Beschichtung garantiert einen effektiven Oberflächenschutz und beginnt bereits bei der beschichtungskonformen Konstruktion des zu bearbeitenden Werkstücks. Bei vielen technischen Anwendungen wird eine PTFE-Beschichtung als Antihaftbeschichtung verwendet und nach einer mechanischen oder chemischen Behandlung aufgetragen. Um hierbei mögliche Fehler bereits im Vorfeld zu vermeiden, unterstützen wir unsere Kunden mit unserer langjährigen Erfahrung und Know-How bei der Gestaltung ihrer Werkstücke nach DIN EN 14879-1, bei der Wahl des zu beschichtenden Grundwerkstoffes sowie bei der Auswahl des Beschichtungswerkstoffes unter Berücksichtigung von chemischer, physikalischer und mechanischer Belastung und unter Gesichtspunkten der Wirtschaftlichkeit. Umfangreiche Beständigkeitslisten stellen wir gerne zur Verfügung.

PTFE-Beschichtung als Korrosionsschutz

Fluorkunststoffbeschichtungen, Duroplastbeschichtungen, Thermoplastbeschichtungen, Pulverbeschichtungen

Gleit- und Antihaftbeschichtungen

Dispersionsbeschichtungen, Pulverbeschichtungen

Verwendete Materialien

E-CTFE-(HALAR®), ETFE, PFA, PFA RUBY RED®, Phenolharze, PROCO-EMAIL schwarz® u.a., Epoxydharze, ChemLINE 784® u.a., Polyesterharze, PA 11(Rilsan®), PTFE-(Teflon®, Greblon®, Xylan®, Ilaflon®), FEP (Teflon®), PFA (Teflon®), MOS2, PEEK, Nanotechnologien

Besonderheiten

Teils lebensmittelkonform, teils mit FDA-Zulassung, auch auf Elastomerwerkstoffen möglich, auch elektrisch leitfähig möglich

Vorbehandlung

Diverse Strahlanlagen bis 10 m Länge für Korund und Glasperlen verschiedener Körnungen

- Strahlen mit Korund nach DIN EN 12944-4

- Entschichten im Pyrolyseverfahren

- Thermisch entfetten

- Chemische Vorbehandlung

Mögliche Kombinationen für verbesserte Abrieb- und Verschleißfestigkeit

- Plasma / Keramik (Al2O3) mit PTFE

- Chrom mit PTFE

- Service-of-the-art – durch alle Schichten

Kapazitäten

- 10 Einbrenn – und Sinteröfen

- Temperaturbereiche bis 500° C

- Stückgewichte bis 8 Tonnen

- Abmessungen bis max. 3,10 m × 3,10 m × 10 m

Außerdem stellen wir Ihnen gerne zur Verfügung

- Alle technischen Datenblätter zu unseren Verfahren siehe www.hueni.de

- Umfangreiche Beständigkeitslisten

Gerne fertigen wir für Sie an

- Beschichtungen von Prüfkörpern für Beständigkeitsversuche

- Musterbeschichtungen

- Außengrundierungen und Decklackierungen

- Mechanische Bearbeitungen

- Werkszeugnisse nach DIN EN 14879-2

Weitere Services

- Abnahmen durch TÜV und andere Prüfgesellschaften

- Schulungen

- Reparaturen

- Logistik

Weitere Informationen

Weitere Informationen finden Sie auch auf der Website unseres Partners HÜNI + CO unter www.hueni.de.

Ansprechpartner

Herr Helmut Kroner

h.kroner@boehme-kunststoff.de

+49 (0)4151 / 88 00-33

Sprechen Sie uns gerne an, wenn Sie eine Beratung zur Antihaftbeschichtung wünschen. Wir stehen Ihnen gern für Rückfragen zur Verfügung.