PTFE-Coated fabrics

MATERIAL WITH OUTSTANDING CHARACTERISTICS

At Böhme-Kunststofftechnik we offer PTFE coated glass fabrics in different versions for standard and as well very demanding applications. The combination of PTFE and glass fabric results in a material with particular properties. The material is temperature resistant (between -150 °C and +260 °C), chemical resistant and has an excellent anti-adhesive surface with a low friction coefficient. Furthermore PTFE coated glass fabrics show a high dielectric strength and dimensional stability. They are stable to UV, IR and HF radiation and reliably defy wetness and other environmental effects. Because of these characteristics PTFE is also increasingly used in architecture.

- architecture

- chemical industry

- food industry

- mechanical engeneering

- packaging industries.

- and many more

- coating for bearings and seals

- linings in chemical plants

- reusable baking sheets

- cover sheet of welding bars during the welding of PE packing films

- and many more

In order to increase the service life of your PTFE glass fabric, we recommend you to use our Boehme Raclette® for cleaning.

Our quality assurance for your products

Customers’ requests are our priority since the beginning. For this reason our efforts are focused on your satisfaction with our products and service. We develop and produce our PTFE glass fabric films exclusively out of high-grade materials with great expertise and modern technology. Thereby it is our aspiration to constantly increase our skills and to develop our products. We are happy to take your requests and suggestions into consideration.

Following you can find our range of standard and premium as well as our Böhme-Expert 2.0® and Böhme-Superior 3.0® qualities.

Non-adhesive

TYPE 2201

thickness: 0,076 mm | PTFE: 53% | weight: 125 g/m² | standard-width: 1000 mm

TYPE 2333

thickness: 0,13 mm | PTFE: 54% | weight: 235 g/m² | standard-width: 1000/1500 mm

TYPE 2370

thickness: 0,14 mm | PTFE: 61% | weight: 270 g/m² | standard-width: 1000 mm

TYPE 2623

thickness: 0,23 mm | PTFE: 55% | weight: 455 g/m² | standard-width: 1000/1500 mm

Self-adhesive

TYPE 3241

thickness: 0,08 mm | PTFE: 53% | weight: 125 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3390

thickness: 0,12 mm | PTFE: 54% | weight: 235 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3449

thickness: 0,14 mm | PTFE: 61% | weight: 270 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3723

thickness: 0,23 mm | PTFE: 55% | weight: 455 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3291

thickness: 0,13 mm | PTFE: 52% | weight: 250 g/m² | standard-width: 1000 mm | acryl adhesive with liner

Non-adhesive

TYPE 2200

thickness: 0,08 mm | PTFE: 68% | weight: 155 g/m² | standard-width: 1000 mm

TYPE 2335

thickness: 0,14 mm | PTFE: 60% | weight: 270 g/m² | standard-width: 1000 mm

TYPE 2377

thickness: 0,15 mm | PTFE: 65% | weight: 310 g/m² | standard-width: 1000 mm

TYPE 2625

thickness: 0,25 mm | PTFE: 62% | weight: 550 g/m² | standard-width: 1000/2000/2600 mm

TYPE 2875

thickness: 0,34 mm | PTFE: 59% | weight: 720 g/m² | standard-width: 1000/1500/2000 mm

Self-adhesive

TYPE 3391

thickness: 0,13 mm | PTFE: 65% | weight: 310 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3450

thickness: 0,15 mm | PTFE: 65% | weight: 310 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3750

thickness: 0,25 mm | PTFE: 62% | weight: 550 g/m² | standard-width: 1000 mm | silicone adhesive with liner

TYPE 3855

thickness: 0,33 mm | PTFE: 62% | weight: 550 g/m² | standard-width: 1000 mm | silicone adhesive with liner

Non-adhesive | usable on both sides

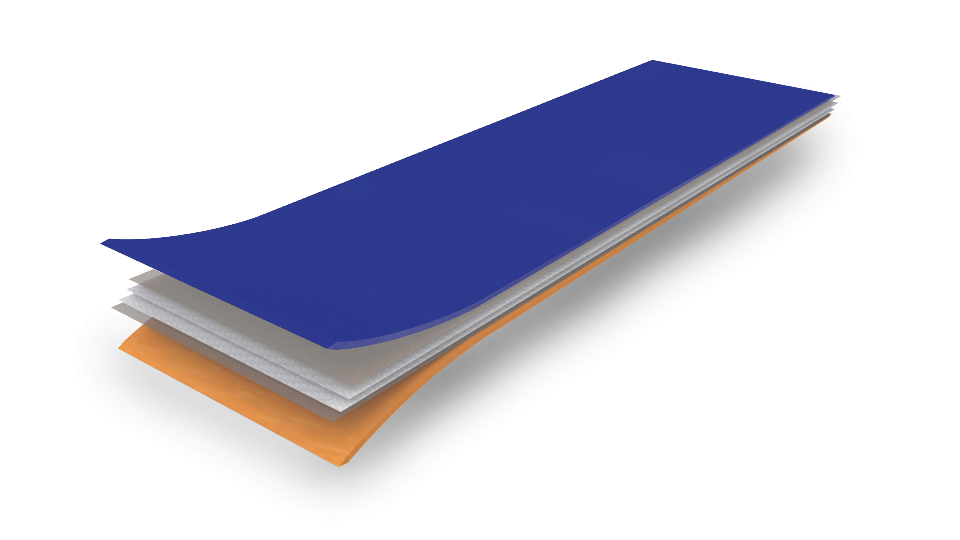

Laminat + PTFE Laminat

thickness: 0,17 mm | PTFE: >65 % | Additional surface treatment | Excellent durability

Non-adhesive | usable on both sides

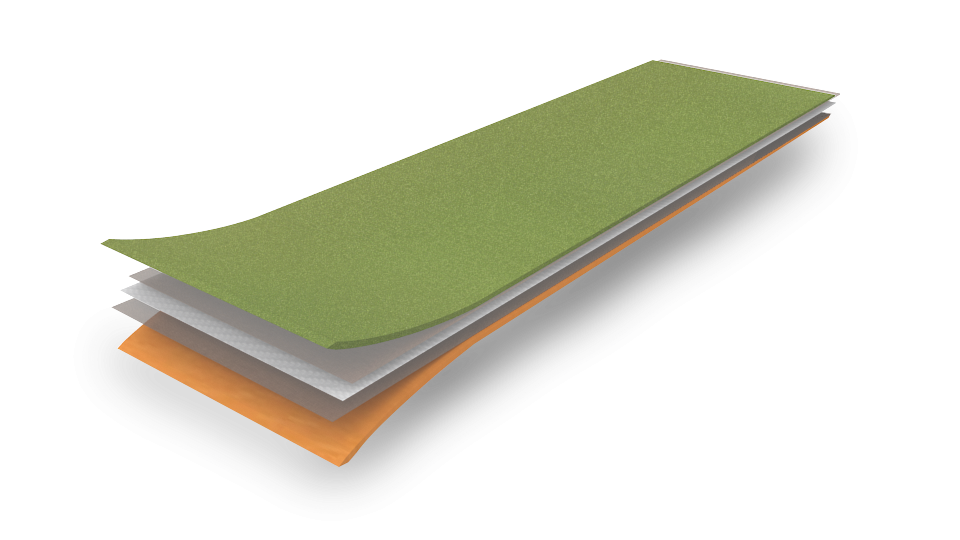

Filmlaminat

thickness: 0,16 mm | PTFE: >65 % | Special PTFE-coating plus PTFE-laminate | Extreme high durability due to anti-adhesive surface

Contact us!

Do you have any questions about our products, individual designs, our quality assurance or would you like advice?